Industrial

Machines

Benchmark for Blow

Moulding Machines

Machines

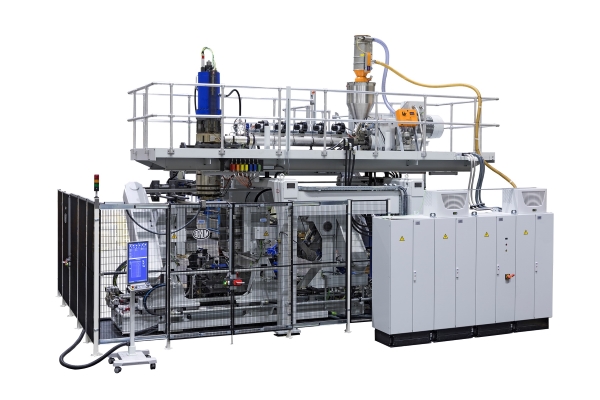

New machine concept for canisters, IBCs, drums, water tanks and a wide range of technical parts

The newly designed XBLOW series includes machine sizes 50, 100, 200 and 300, which are available as single-station machines.

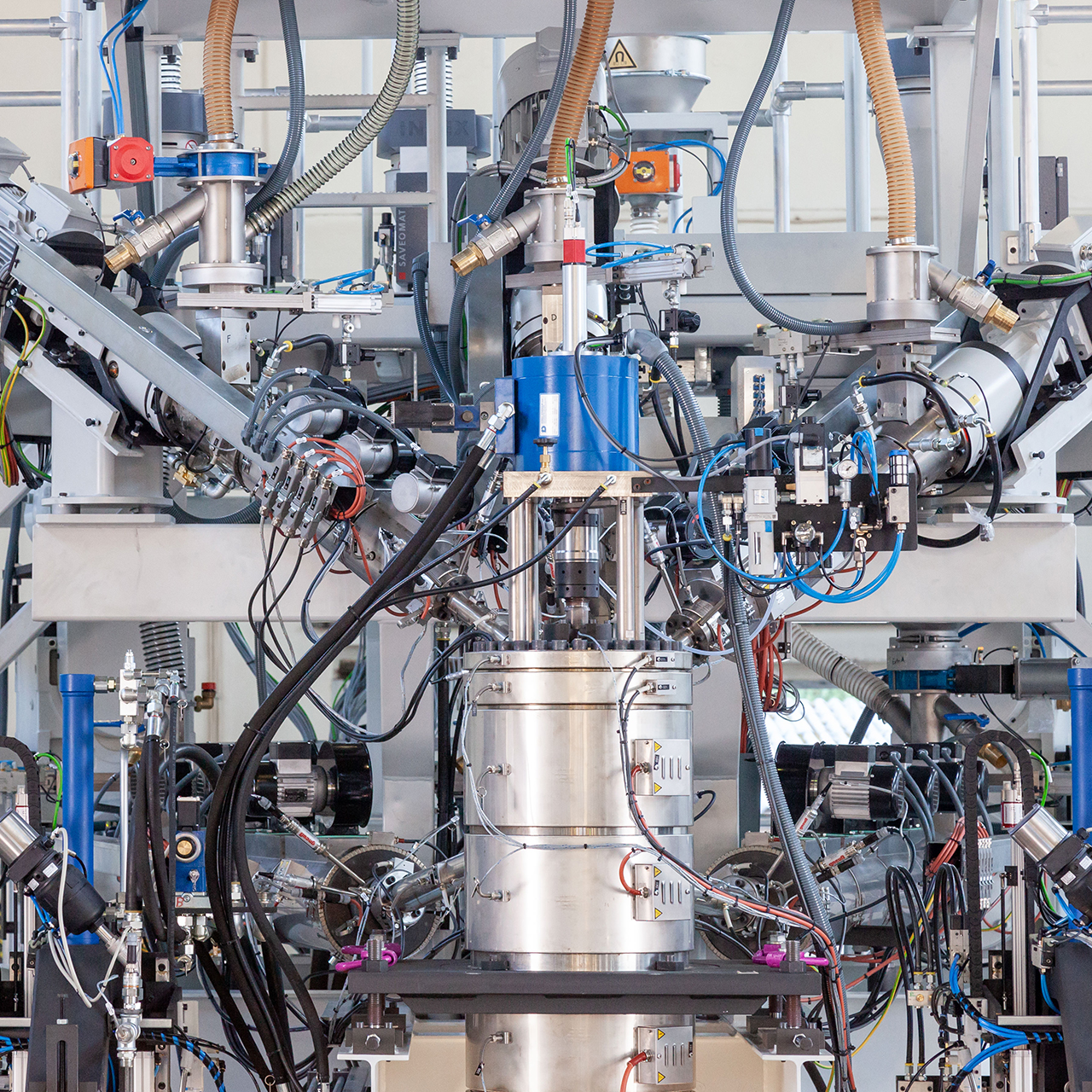

The centerpiece is the new patent-pending clamping unit with diagonally arranged tie-bars and a two-stage hybrid-electric clamping drive for clamping forces of 500 – 3.000 kN. The use of servo hydraulics has significantly reduced energy requirements. The use of blow moulds of different thicknesses has been taken into account in the design, and the operator can conveniently and easily adjust very large variable mould thicknesses that are not possible with other electric clamping drives of large blow moulding systems, via the new Bekum Control 8.0 machine control system on the HMI. This system does not need to be mechanically adjusted. While the clamping unit is centrally located under the platform, continuous heads require a laterally offset position. Modern and quiet speed-controlled hydraulic units reduce energy consumption and reduce the noise level to 71 dB(A).

Advantages at a glance:

Advantages at a glance:

• Flexible and modular industrial blow moulding systems with high accessibility and flexible production solutions for large canisters, drums and IBCs

• Unique hybrid electric clamping concept up to 3,000 kN, fast, energy-saving and with unique mould thickness variance (patent pending)

• Rapid stroke movement electrically and hydraulically. Hydraulic mould functions and accumulator heads driven by variable-speed hydraulic power unit.

• Can be equipped with bottom calibration, blowing and spreading blow pins, as well as horizontal and vertical parison transfer devices.

• Complete production solutions including moulds, robots, post-processing or post-cooling stations and material handling from a single source, i.e. for 220L ring drums.

• Intuitive Bekum Control 8.0 control with AI monitoring for continuous article quality and highest line availability

• High-performance HiPEx 36D extruder with homogeneous melting and process stability with -20% energy consumption

• Modern simulation-supported spiral mandrel extrusion heads, as accumulator head and continuous for mono to co-extrusion. Melt and temperature homogeneous with short colour change times

Machines

Features

XBLOW 100

| Technical Specification | ||||||

| Single and Twin-station Extrusion Blow Moulding Machine | EBLOW 38S* EBLOW 38D* |

XBLOW 50 | XBLOW 100 | XBLOW 200 | XBLOW 300* | |

|---|---|---|---|---|---|---|

| Clamping force (kN) | 400 | 500 | 1.000 | 2.000 | 3.000 | |

| Clamping force (US t) | 45 | 56,2 | 112,4 | 224,8 | 337,2 | |

| Mould width, max. (mm) | 780 | 800 | 1.200 | 1.500 | 2.200 | |

| Mould length, max (mm) | 750 | 800 | 1.500 | 1.800 | 2.200 | |

| Mould depth (mm) | 2 x 200 2 x 250 |

2 x 250 2 x 350 |

2 x 300 2 x 470 |

2 x 400 2 x 650 |

2 x 500 2 x 700 |

|

| Day light opening (mm) | 400 | 700 | 850 | 1.200 | 1,200 | |

| Mould carriage stroke (mm) | 720 / 780 750 / 800 |

|||||

| Production possibilities per mould, max. (l) |

30 | 60 | 250 | 1.000 | > 1.000 | |

Machine standard is bold.

* available from 2023